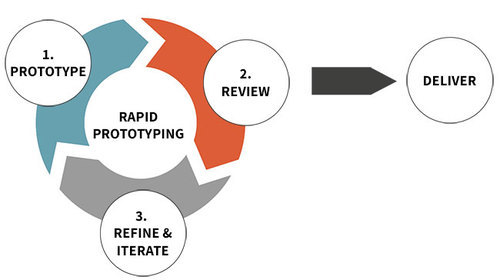

Rapid prototyping processes comprise techniques used to make a product prototype with the aid of CAD software. It is an important process in manufacturing due to benefits such as reduction of lead time, ability to check errors, improvement of production efficiency, etc.

There are many techniques used in rapid prototyping. Common machining techniques include CNC machining, injection molding, and 3D printing. Choosing the right method is not a straightforward process as several factors play a huge role in the decision-making. To make selecting the right method easier, this article will discuss three important rapid prototyping methods and the factors that play a huge role in choosing the right one.

Rapid Prototyping Methods You Can Use?

Rapid prototyping comprises different processes used in different scenarios. Therefore, to know the right rapid prototyping method to use, there is a need to know the different techniques. Below is an explanation of the three common rapid prototyping methods used in many industries.

-

CNC Machining

CNC machining is a manufacturing process that involves using a computer program to coordinate tools and machinery towards manufacturing a product. It is a subtractive manufacturing process, i.e., the tools and machinery, e.g., lathes, grinders, millers, etc., cut away parts of the material.

The subtractive process is based on the CAD file already uploaded to the computer, and it decides the final product. CNC machining is a popular rapid prototyping method used in different industries and scenarios.

-

Injection Molding

Injection molding is a manufacturing process that involves injecting molten materials into an already created mold. The molten material cools downs and solidifies to form the finished product. Injection molding is a popular rapid prototyping method in industries requiring mass production of materials, e.g., plastic processing industries.

-

3D Printing

3D printing prototyping is another manufacturing process similar to the CNC prototyping machining process since it is based on the use of CAD software/files. However, unlike CNC prototyping machining, it is an additive manufacturing process. Instead of the software directing the machines to cut away, production occurs by laying down successive layers of the material. These layers are a sliced cross-section of the object, and they can be tweaked as required. Consequently, 3D printing is ideal for making complex shapes of products.

The Function Of Your Prototyping/ The Purpose

The function of the prototype plays a huge role in the rapid prototyping method to use. Rapid prototyping is different at every unique stage. There are four common stages each with its features and therefore the recommended method:

-

Discussion of Design Ideas Stage

This is the first stage, and it requires the use of an early model for the accurate presentation of a design idea. Since the early models are mock-ups and mostly one, CNC machining and 3D printing are ideal rapid prototyping methods.

-

Conceptualization Stage

This stage requires you to clarify the functionality and form of the product. This includes getting the shape, size, and other outlines of the product in the prototype. The right rapid prototyping method depends more on the materials and cost. 3D printing is the ideal method. However, if the material is metal, CNC machining is a better choice.

-

Implementation Stage

In this stage, the functionality of the product will be tested. Therefore, details are very important. Since this stage requires multiple prototypes due to the high need for modification, injection molding is the best choice. However, you can also employ high-resolution 3D printing.

-

Detailed Design Stage

Prototypes manufactured at this stage are likely pre-production proofs. If there is a need for multiplicity, which is inherent, injection molding is the most compatible method.

Quality

The quality of the prototype you want determines the type of rapid prototyping method for you. It shows whether you have achieved the purpose of prototyping. This is because the prototype must be similar to the projected product.

You can make a low-quality prototype if your team values functionality over appearance. It is an easy and economical way to make a prototype, and production is achievable via 3D printing or CNC machining.

You can also make a high-quality prototype with a huge similarity to the projected product. This is important when there is a need to test both functionality and visual appearance. Both properties give the team and customers what to expect regarding how the projected product will work. High-quality prototypes require high precision, low tolerance, etc., and this is achievable via CNC machining or injection molding.

Complexity

The complexity of the prototype also plays a huge role in the type of rapid prototyping process to use. When dealing with complex parts that feature hollow designs, the ideal method to use is 3D printing. However, while the method can produce small complex parts, it can be expensive when mass produced. In such a scenario, you might need to use injection molding.

Desired Quantity

The desired quantity of prototypes is another huge factor to reckon with when choosing rapid prototyping methods. The ideal method to use in mass production is the injection molding process. Using 3D Printing and CNC machining are only cost-effective for small quantities. Therefore, unless necessary, additive, and subtractive manufacturing methods should be avoided in mass production.

The Type of Material You Need

The type of material your product and prototype are made of also plays a huge role in choosing the right rapid prototyping method. Both 3D Printing and CNC machining have a wide range of compatible materials. Below are a few materials compatible with each technique:

- 3D printing: Nylon, PLA, ABS, ASA, TPU, aluminum, stainless steel, titanium, chrome-nickel-iron alloys

- CNC machining: ABS, nylon, polycarbonate, PEEK, aluminum, stainless steel, titanium, and brass

- Injection molding: Plastic and nylon materials.

What Is Your Budget?

This is the most important determining factor of the right rapid prototyping method. Due to the machines required and the number of parts needed, some rapid prototyping methods are more costly. For example, CNC machining is costly, especially when used in making complex products or in mass production (which is unideal). 3D printing is less costly than CNC machining. However, when used in mass production, it becomes costlier. Of the three rapid prototyping methods discussed above, injection molding is the most balanced.

Lead Time

The lead time should also be taken into consideration when choosing a prototype method. Below are the characteristics of the above rapid prototyping methods with relation to their lead time:

- 3D printing: It takes a little post-processing time. However, it is fast.

- CNC machining: The lead time of CNC machining depends on the complexity of the design.

- Injection molding: It is very fast, which is evident in its use in mass production.

Final Thoughts

Rapid prototyping processes are now an integral part of many manufacturing industries due to the need for quality testing. However, the success of prototyping depends on the selection of the right method. Therefore, this article discussed several factors that will help with selecting the right rapid prototyping method.

With a clear understanding of the factors above, you can decide on the right method to use. Rapid prototyping companies like RapidDirect, have a clear understanding of all the listed rapid prototyping methods. This includes their limitations, materials needed, etc. Our team of experts is highly knowledgeable and will help you get the best out of your design.